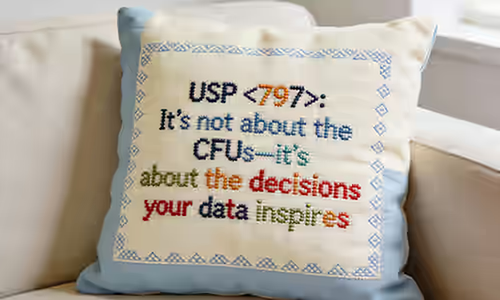

6 Common Pitfalls in USP <797> Data Trending—And How to Fix Them

- By: Rhonda Lintner, MPH, B.S.

- Tags: USP 797

6 Common Pitfalls in USP <797> Data Trending—And How to Fix Them

Has adherence to USP 797 started to feel like a checkbox exercise? Take samples, count CFUs, compare results to USP 797 action levels, file the environmental monitoring report—as long as the CFU counts stay under the limits, it’s all good…right?

Or is it? The USP 797 standard requires compounding pharmacies to build an effective monitoring program. Because the standard focuses on minimum requirements, it leaves many details open, which means each facility must assess its own risks and design a program that truly protects patients. As we discussed in a recent post, data trending is such an essential component of meaningful environmental monitoring the authors of the USP 797 standard made it a requirement. If you missed that post, you can catch up here: The Importance of Trending in USP <797> data compliance.

In today’s post, I’m going to highlight the most common missteps we see and how a well-designed trending program can correct them.

#1: Treating Consistent “No Exceedances” As Success

This one can seem counterintuitive, so it’s a good place to start. One of the biggest conceptual misunderstandings compounding pharmacies have is the assumption that a year of spotless reports means your engineering controls, personnel competencies, and processes are all up to snuff. In reality, never seeing an action-level exceedance may say more about your sampling and review practices than about the actual state of your facilities and personnel.

How to fix it: In a healthy sampling program that consistently follows defined protocols, some degree of variation is expected. Regularly reviewing trending data helps you determine whether your USP 797 sampling results are genuinely positive or simply too good to be true.

#2: Not Looking at Trends by Microorganism

As noted in another recent post, two samples with identical CFU counts can represent very different levels of concern depending on which microorganisms are present. One sample may be dominated by typical skin flora, while another may contain environmental molds such as Aspergillus—and each tells a different story about system performance and potential risk.

However, in the context of USP 797, the primary question is not simply whether an organism is “pathogenic” in the traditional clinical sense, but what its presence, persistence, and trends reveal about your quality controls and the likelihood of contamination reaching the patient. Even microorganisms that are usually considered low risk in everyday settings can pose a serious hazard if introduced into the bloodstream through a compounded sterile preparation.

Without genus-level trending, a facility may miss a slow, steady increase in specific microorganisms that signal emerging problems long before action levels are exceeded. For example, a rise in CFUs of Staphylococcus epidermidis, a common skin organism, may point to gaps in hand hygiene or gowning technique. An effective environmental monitoring program uses organism identification as an early warning system, treating trends as cues to review procedures, engineering controls, and personnel competencies to protect patient safety.

How to Fix It: Choose a laboratory with proven expertise in genus identification, recognizing that this is a highly specialized skill set that often requires a trained microbiologist.

#3: Using Too Few Data Points to Define a Trend

A single data point—or even two or three—does not make a trend. When interpreting USP 797 data, the “rule of seven” is a good one to follow. Frequently used in quality control philosophies, such as Six Sigma, the rule of seven states: If seven consecutive points fall on one side of the mean or move in one direction, the probability that the pattern is due to random variation drops enough that you should treat it as a real signal.

Using fewer than seven data points for decision-making can hide real problems or create “phantom” issues that don’t actually exist. A one‑time spike tied to an unusual traffic pattern or weather event looks alarming but becomes clearly identifiable as an outlier when additional data points are added. Conversely, a gradual upward drift in CFU counts or a slow shift in the types of organisms identified is far more difficult to see without a statistically meaningful trend line.

How to Fix it: Use seven or more data points in your trend line. For some facilities, this may require implementing better trending documentation or dashboards.

#4: Mixing Data from Different Rooms, PECs, and Personnel in One Trend Line

Another subtle but common problem is lumping data into a single dataset. Blending results this way can mask localized problems or even create apparent trends where none exist. For example, combining data from a hazardous drug buffer room with a non-hazardous laminar flow hood may average out meaningful spikes tied to a single area or workflow. USP 797 expects entities to use a risk-based approach and evaluate each classified area and PEC on its own merits.

How to fix it: Trending should reflect that structure: separate datasets for each room and PEC, with the ability to drill down by operator or shift when recurring issues emerge. Only then can trending reliably tell you where a problem is developing and who or what is driving it.

#5: Confusing Environmental “Noise” With Real Trends

Compounding pharmacies do not operate in a vacuum in the real world. For example, high winds can kick up dust and debris, overloading HVAC systems and temporarily increasing airborne contaminants. Similarly, an atypical traffic pattern, such as a one-off rush of staff through an anteroom, can elevate counts in a way that does not reflect day-to-day operations.

These events are “environmental noise,” but that does not mean they should be ignored. A robust trending program distinguishes between noise, emerging trends, and true excursions, and then documents the rationale.

How to fix it: Correlate abnormal results with engineering data (HVAC performance, room pressurization), people data (staffing and traffic patterns), and workflow events to decide whether the finding represents a one-time anomaly, a correctable process issue, or a sign of deeper control problems.

#6: Failing to Respond Strategically to USP 797 Trend Data

The USP 797 standard requires compounding pharmacies to monitor and respond to trend data, but any changes must be data-driven and properly documented. For example, over an 18-month sampling period, one pharmacy consistently recovered microorganisms from a specific piece of IT equipment. After identifying and documenting this recurring issue, the pharmacy implemented targeted changes to reduce the risk of contamination associated with that equipment.

Even though these adjustments may appear minor, it’s critical to record both the modifications and the rationale behind them. Arbitrary changes made without sufficient analysis or documentation can weaken your quality control program and raise red flags during audits. Auditors may ask about the basis for any change and expect a clear explanation supported by data and written justification. Failing to provide that clarity not only compromises compliance with USP 797 expectations but also signals potential gaps in your overall contamination control strategy.

How to fix it: Clearly document sampling results, subsequent risk assessments, mitigation steps, and justification for modifying the plan.

Build a USP <797> Trending Program That Truly Protects Patients

The real value of USP 797 environmental monitoring and data trending is measured in the quality of the decisions it drives, not just in the CFU numbers on a report. A compounding pharmacy that uses trend data to detect subtle shifts, investigate root causes, and implement documented corrective actions is far more likely to maintain a state of control than one that only checks results against action levels.

Need help designing or refining an environmental monitoring and data trending program, including what to trend, how to interpret microbial patterns, and when to move from CFU-only counts to full genus identification? Our USP 797 specialists can work with you to build a program that meets regulatory expectations and your specific risk profile.