Experienced & Reliable Lab Equipment Repair & Maintenance

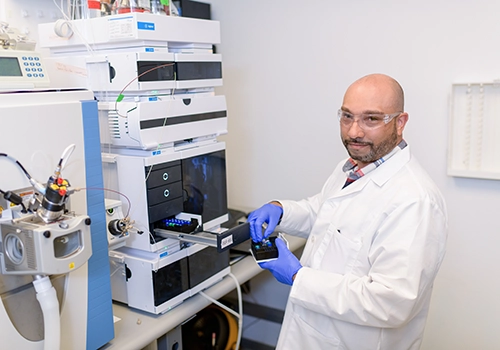

Achieve your desired results while avoiding expensive downtime with our lab equipment maintenance and repair services. We operate with efficiency by providing multi-vendor support powered by original equipment manufacturer (OEM) traceable training across various analytical instruments and scientific equipment suppliers.

Our ISO 9001:2015 accredited experts deliver the level of service, support, and ongoing product knowledge needed to keep your laboratory instruments in peak condition.

Scientific Instrument Services & Equipment Maintenance

Whether your facility is equipped for research, testing, production, or other purposes, each setting has its own set of characteristics, requirements, and restrictions. With decades of experience across diverse labs and industries, our technicians are mindful of your investments and expectations, ensuring the delivery of the most fitting services for your needs.

Our team is trained to service a wide range of instrumentation across various equipment manufacturers, enabling greater responsiveness and adaptability to your evolving needs.

- High-performance liquid chromatography (HPLC)

- Ultra (high) performance liquid chromatography (UPLC, UHPLC)

- Ion Chromatography (IC)

- Liquid Chromatography (LC, LC-MS)

- Gas Chromatography (GC, GC-MS)

- Dissolution

Our experience with multiple OEMs not only sharpens our problem-solving abilities for addressing your facility's unique needs but also allows you to consolidate service contracts through our multi-vendor support.

- AB Sciex

- Agilent

- CTC Analytics Multi-Samplers

- Distek

- Hanson

- Shimadzu

- Thermo/Dionex

- Waters

Our expert technicians perform equipment qualifications on water systems, compressed air and gas systems, HVAC systems, autoclaves, stability chambers, incubators, refrigerators, freezers, ovens, and other equipment that has specific user requirements. We provide documented verification that your equipment complies with engineering design specifications and requirements.

- User Requirements (URS)

- Design Qualifications (DQ)

- Installation Qualification (IQ)

- Operational Qualification (OQ)

- Performance Qualification (PQ)

- Chamber Mapping

- Certification

Our technicians are highly skilled at certifying biological safety cabinets (BSC), laminar flow HEPA workstations, fume hoods, compounding isolators and other equipment that has specific user requirements.

- HEPA Filter Integrity

- HEPA Filter Velocity

- Airflow Visualization

- Viable Air Sampling

- Viable Surface Sampling

- Temperature & Humidity Uniformity

- IQ/OQ/PQ

Flexible Service Options

Each facility has its own operational requirements and restrictions, which is why we provide versatile instrument servicing options to best meet your business needs. Whether you’re looking for full-service contracts, a dedicated resource, or time and material arrangements, our team is ready to help.

Service Agreements

Traditional service contracts include maintenance, repair, and qualification options. All our plans are supported by OEM traceable trained technicians and include same day remote support and 24-hour emergency response times.

Dedicated Resources

An instrument service technician remains onsite at your location to oversee daily maintenance and routine service. We also offer training and trouble-shooting tips to end users and respond to repairs immediately.

Time And Materials

Our arrangements are designed to provide fast, responsive, and reliable service when you need it. Our team’s vast multi-vendor instrumentation knowledge, including legacy and newer models, allow us to address challenges straight away, rather than require repeat service visits.