Protect Your Workforce with Reliable Respirable Crystalline Silica Testing Solutions

At Pace®, our AIHA IHLAP accredited (Lab ID: LAP-101526) Respirable Crystalline Silica (RCS) testing services help organizations maintain compliance with OSHA and other regulatory standards while protecting worker health and safety. Using advanced analytical methods such as X-ray diffraction (XRD), our experienced scientists accurately quantify silica concentrations in air and bulk samples. We offer rapid turnaround times, precise detection limits, and comprehensive reporting to support industrial hygiene assessments, exposure monitoring, and environmental investigations.

to learn more about our Respirable Crystalline Silica testing services.

What is Crystalline Silica?

Crystalline silica is one of Earth’s most abundant minerals. Its use dates back to ancient civilizations, where it was crafted into jewelry, tools, and building materials. In contemporary applications, crystalline silica has evolved to play a crucial role in producing ultra-pure glass for optical devices, tempered glass, specialized quartz glassware, high-temperature ceramics, and advanced materials for aerospace and other high-tech sectors.

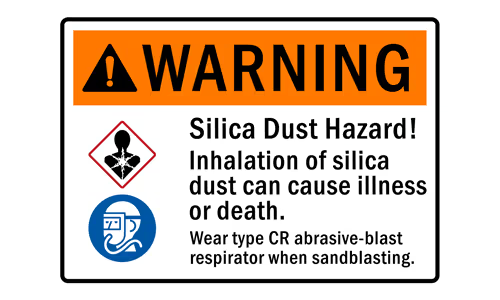

What Are the Health Hazards Of Crystalline Silica?

Today, individuals from diverse backgrounds encounter crystalline silica regularly, and for the majority, exposure poses minimal risk. However, those employed in construction, sandblasting, foundries and mining may face significant exposure to respirable crystalline silica, increasing their risk of developing silicosis, a serious and potentially fatal lung condition.

Accurate Detection and Sampling of

Respirable Crystalline Silica (RCS)

X-ray Diffraction (XRD) remains the gold standard for precise detection and quantification of crystalline silica, adhering to established methods such as OSHA ID-142 and NIOSH 7500. It effectively identifies the three major crystalline forms — α-quartz, cristobalite, and tridymite.

Samples are collected using personal or static samplers equipped with PVC filters (pre-weighed filters can be requested if total respirable dust data are needed) and size-selective devices (such as nylon or aluminum cyclones or parallel particle impactors). The sampling and analytical approach depends on the exposure scenario, regulatory framework, dust composition, and desired detection sensitivity.

How is Respirable Crystalline Silica Regulated?

Respirable Crystalline Silica (RCS) is regulated in the United States primarily through federal standards set by OSHA, MSHA, and NIOSH along with additional state regulations such as those by Cal/OSHA.

MSHA is responsible for protecting the health and safety of miners in the United States. To limit respirable crystalline silica (RCS) exposure, MSHA has established a permissible exposure limit (PEL) of 50 micrograms per cubic meter of air (µg/m³), measured as an 8-hour time-weighted average (TWA). When exposures reach or exceed 25 µg/m³ (8-hour TWA), employers are required to conduct periodic sampling, even if the PEL itself is not exceeded.

OSHA develops and enforces workplace health and safety standards across most industries. OSHA’s silica standards set a PEL of 50 µg/m³ (8-hour TWA) under two separate rules—one for general industry and maritime and another for construction. Employers must implement engineering and work practice controls, perform exposure assessments, provide medical surveillance, offer worker training, and maintain detailed exposure records. Additional requirements apply to high-exposure tasks, particularly those involving dust-generating construction operations.

The National Institute for Occupational Safety and Health (NIOSH), part of the Centers for Disease Control and Prevention (CDC) within the U.S. Department of Health and Human Services, conducts research and provides recommendations to prevent work-related illnesses. For respirable crystalline silica, NIOSH has established a Recommended Exposure Limit (REL) of 0.05 mg/m³ (50 µg/m³) as an 8-hour TWA, consistent with OSHA and MSHA limits. NIOSH identifies crystalline silica as a potential occupational carcinogen and recommends the use of engineering controls, exposure monitoring, and appropriate respiratory protection in environments with elevated silica concentrations.

Some states have adopted more stringent silica control measures beyond federal requirements. For example, California may issue Emergency Temporary Standards (ETS), mandate specific task-based exposure controls, or require additional medical surveillance for workers in high-risk industries. Employers must review and comply with both federal and state-level standards to ensure full regulatory compliance.

Partner With Pace® for Reliable Silica Analysis

With decades of experience in environmental and occupational testing, Pace® delivers the accuracy, speed, and regulatory insight organizations rely on to protect their workforce and meet compliance obligations.