Reliable Cleanroom Services to Maintain Optimal Operations

Satisfy your safety and compliance standards with our routine cleanroom testing and certification services. Whether you plan to launch a new space or maintain existing facilities, we have the knowledge and experience you need to ensure your space adheres to stringent regulatory requirements.

Our testing services comply with multiple industry standards, including Current Good Manufacturing Practices (cGMP), Institute of Environmental Sciences Technologies (IEST), and International Organization for Standardization (ISO) and USP <797>. We have various locations across the country to provide you with flexible, responsive services that align to your program’s unique needs. We take on a variety of projects, from biosafety cabinet certification to supporting the launch of entire new facilities.

Certification & Testing Services

Gain confidence in your controlled environment with certification performed by our highly trained professionals. We are committed to aligning with your operations schedule to ensure your facility achieves compliance with minimal downtime or interruptions.

- Particle Counts

- HEPA Filter Integrity

- HEPA Filter Velocity/Volume

- Room Air Changes

- Room Pressure

- Viable Air Sampling

- Viable Surface Sampling

- Temperature & Humidity Uniformity

- Room Recovery

- Installation Qualification (IQ)

- Operational Qualification (OQ)

- Performance Qualification (PQ)

Reliable facilities hinge on dependable equipment, which is why certifying your equipment on a regular basis is so important. Our team of skilled professionals provide certification for biosafety cabinets, fume hoods, laminar flow hoods, compounding isolators, and other equipment that has specific user requirements.

- HEPA Filter Integrity

- Face Velocity Readings

- Particle Counts

- Airflow Visualization

- Viable Air Sampling

- Viable Surface Sampling

Ensure compliance with engineering design specifications and requirements by leveraging our trusted facility qualification services. We have experience across a diverse range of manufacturing, testing, and production environments to serve your unique needs and provide documented verification of required conditions.

- User Requirements (URS)

- Design Qualifications (DQ)

- IQ OQ PQ

- Certification

- Custom Protocol Creation

Verify that your equipment is suitable for its intended purpose and operates within defined parameters and specifications with our team’s equipment qualifications services. We qualify water systems, compressed air and gas systems, HVAC systems, autoclaves, stability chambers, incubators, refrigerators, freezers, ovens, hoods, and other equipment that has specific user requirements.

- User Requirements (URS)

- Design Qualifications (DQ)

- IQ OQ PQ

- Chamber Mapping

- Certification

Meet the precise standards of USP General Chapter <797> and USP General Chapter <800> with our reliable pharmacy certification services. Our services include certification of all primary engineering controls (BSC, LAFW, CI/CACI), viable and non-viable particulate, HEPA integrity, room air changes, room pressurization, and static/dynamic airflow visualization video. Additionally, we test USP <825> radiopharmaceutical spaces.

Maintain your controlled environment’s compressed gas and air lines with routine cleanroom systems monitoring. We perform testing at any step of your process and provide custom reports that include test results and a map of testing locations.

- Particulate

- Viable Organism

- Moisture/Dewpoint

- Oil/Hydrocarbon

- Pressure

- IQ OQ PQ

We offer comprehensive services to create a customized approach suited to your unique requirements. Whether you need help with planning, set up, maintenance, or remediation, our team is prepared to support your facilities in a variety of ways.

- CEA HVAC Test & Balance Work

- Contamination Control Consulting

- Contamination Control Audit

- HEPA Filter Replacement

- Installation of Monitoring Systems

What You Need To Know About Cleanrooms

Supporting Optimal Operations & Compliance

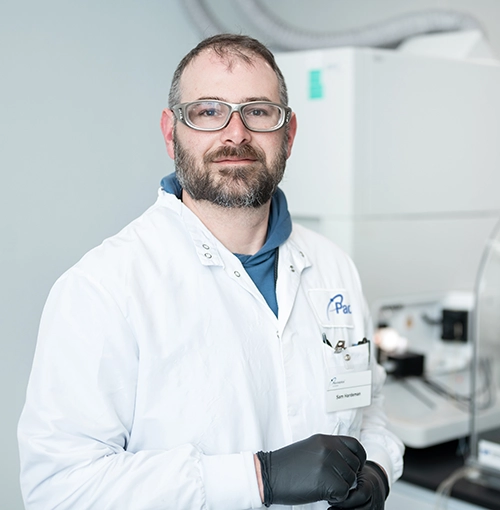

Trained Technicians

Our highly trained technicians use specialized instruments to offer support at any point in the certification process.

Experienced Microbiologists

Our experienced microbiologists offer testing services performed in compliance with current USP/NF, and client-supplied methodologies.

Expert Consultants

Our consulting team supports compliance strategy, master planning, validation, and contract services to ensure your facility satisfies industry standards.

Proven Performance

Request a Cleanroom Quote

Maintaining cleanrooms requires responsive, reliable support. Kickstart the conversation about how we can support your cleanroom operations and compliance by providing key context to begin the quoting process. Our team takes in this background information, identifies any remaining gaps, and follows up to your request in a timely manner.

Integrated Laboratory Services

RESOURCES

TERMS

Installation Qualification (IQ)

Operational Qualification (OQ)

Performance Qualification (PQ)

CLEANROOM GUIDES

ISO 14644-1 Cleanroom Standard

EU Guidelines to Good Manufacturing Practice

USP <797> Services and Supplies Overview

CERTIFICATIONS

A2LA, BSI, CETA, ISO9001, NEBB

|  |  |  |

To help ensure compliance with USP General Chapter <797> and USP General Chapter <800>, our CETA National Board of Testing certified staff provide all required pharmacy cleanroom testing and certification.